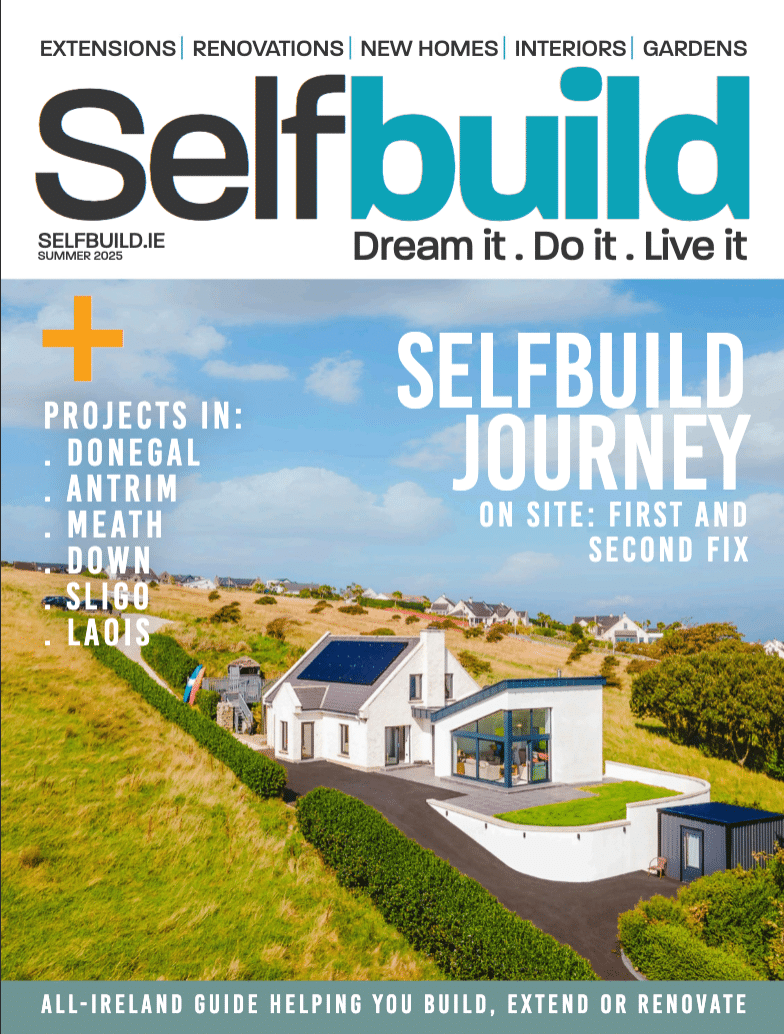

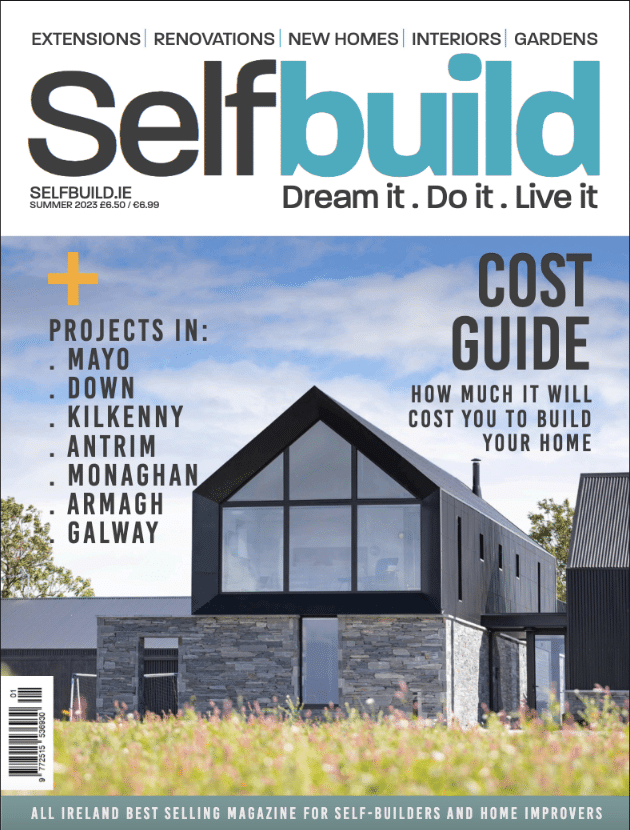

John and Susan Black of Co Antrim had a narrow and sloping site, yet they still managed to build their dream home.

In this article we cover:

- Details of the site and how they had to think differently about design

- Redesign process after securing planning permission

- Designing a house in an Area of Outstanding Beauty

- Details of room uses from top to bottom on the three storey house

- Choosing the right builder for the project

- Insulation and airtightness strategy

- Choice of heating and ventilation systems

- Choice of windows and restrictions for fire regulations

- Full specification and supplier list

Being granted planning permission is, in most cases, a cause to celebrate. However for John and Susan it was a bit of an anti-climax as they soon realised the house they’d planned to build didn’t fit the site.

Construction: tanked basement (from inside to outside: 140mm masonry, 100mm cavity, 300mm poured concrete, self-adhesive tanking membrane), two stories built above with 100mm cavity walls; structural steel supports on first floor. Ground floor prefabricated concrete slab. Exterior finished with smooth sand/cement render.

Insulation: walls filled with EPS graphite beads U-Value 0.29 W/sqmK, at dormers 100mm PIR U-Value 0.17 W/sqmK; roof 300mm fibreglass U-Value 0.12 W/sqmK, floors 100mm PIR U-Value 0.17 W/sqmK

Airtightness result: 3.2 m3/h.sqm

Windows: double glazed, uPVC, argon filled, low-e

EPC: B (81)

“The plot was quite challenging being narrow, with one side facing the road and the other a river,” explains John. “There’s also a 1:8 slope, which makes it all the more complicated. The drawings we had at the time seemed to have been copied from standard plans; what we were in need of was a much more bespoke design due to the topography.”

Plotting around planners

In an Area of Outstanding Natural Beauty, which is where John and Susan had their site, there are more planning restrictions than if you were to build on greenfield. Knowing what they were up against they decided to hire an architect they felt displayed an aptitude for design and a strong ability to deal with the planners.

“We were knocking down a house that was over 100 years old which many people drove past, and indeed had fond memories of the original dwelling,” says John. “For fear of not getting planning and because we were novices, we accepted the design we were given.”

“It was made to look like a typical home from the 1990s, quite traditional, not exceptionally well laid out or sympathetic to the site and truth be told, we weren’t that keen on it.”

As expected, they were granted planning permission. “When we started to clear the site it became obvious the house design wouldn’t fit… There were other problems such as the back door opening out onto the river. At that stage we decided to look for another architectural practice,” adds John.

“Most of the architects suggested a split level design, which made the most sense. The team we chose was able to turn the concept into an image very quickly, which was a difficult task due to the challenging site conditions.”

“The architectural practice that represented us is young and very dynamic, they were excited about the project and that was important to us. Of course the big difference with the new design was that it fitted the site and accentuated its best features.”

“Perhaps most important of all, they told us we didn’t have to settle for a house we didn’t like simply because of planning. So when we had the option to change the design, we put in as much as we could think of, including glazing and contemporary smooth finishes on the outside,” continues John.

“When we agreed on the plans, the architects came up with a number of details they thought the planners might not accept, luckily we didn’t care too much about some of them. In the end practically everything was delivered. The only thing I remember that was turned down is the chimney breast; they told us it couldn’t be built proud of the wall.”

The architect’s attention to detail extended to the finishes; an example includes the oak skirting boards which are plain and simple, in keeping with the contemporary feel. Every element was thought of and that shone through in the negotiations.

“With the planners it’s a debating game, and while our house is contemporary for the area it’s still sympathetic to its location. The practice we hired is energetic, their ideas and vision pushed the project through. The planners were more flexible than we originally thought they might be; we gained planning permission without too much trouble.”

Hug the slope

“The 30 to 40ft (9 to 12m) drop back to the river meant we were very constrained. The challenge was to make the maximum use of space,” adds John. “So the garage and utility are in the basement and the living and sleeping quarters above ground.”

As per best practice, the house was built along the slope. “The front door is on an incline and we park on the main drive. The house is spacious and everything fits so well. When people come to visit they comment on the amount of room we have created in our home.”

The problem with a site such as this one is that a flood risk assessment and a site analysis had to be carried out. “A significant amount of money was spent before we were even out of the ground,” says John. “There’s rock underneath and the river had to be managed during construction. The architect had to consult these studies when he decided how to build the basement and what tanking method was most suitable.”

Living near a river may have its downside but it does bring with it some exciting views. In fact much of the modern element of this build has to do with its approach to glazing. “The windows capture the views to the river and those parallel to the road provide added interest,” adds John.

“We wanted loads of glass with an open plan layout, a house that felt it had a bit of character and was practical to live in. The last thing I wanted was the middle of the house to be dark and pokey.”

The bedrooms are different shapes and sizes, and the architect used light in alternative ways in each of them. “Every room has its own character,” adds John. Indeed, the benefit of the sloping site is how unique it is, preventing the rooms from being perfectly square.

“On a practical level, the window cleaner does complain about how difficult it is to wash some of them because of the slope. The second fix was also a bit less straightforward than if we had had 90 degree angles everywhere, but it wasn’t a major issue.”

In order to turn the architects’ vision into reality, the services of a structural engineer were required. “We needed structural steel support as the open plan is vaulted and spans from the kitchen to the living area; we also have a glass wall that had to be supported,” says John. “We were aware that the glass would get a fair battering during the winter so we chose a high specification window to deal with the vagaries of the local weather.”

Bespoke tender

“My wife and I were both working and combined with a young family we were kept fairly busy,” says John. “We didn’t have the time or energy to have a large involvement so we chose to get a building contractor. I have an engineering background and with advice from guys I had worked with we were able to put together the tender package ourselves.”

“Our architect gave us drawings and from that we drew up the list of what we wanted, with as much detail as we could. We then got builders to price it. Even though we encouraged them to give us information on cost and type of products to be used, especially if they felt something wasn’t clear, only two came back with detailed quotations.”

John says to look out for consistency between the drawings and the bid. “Our tender document was only two pages long, in addition to the architect’s plans. What mattered to us were the specifications that the builders came back with. Make sure to ask for details from them, not a lump sum price.”

“Through the grapevine we chose the company we felt had the right maturity and calibre,” adds John. “They’re well experienced, have completed lots of single one-off houses and take pride in their work. What we got as a result was a good builder who was completely transparent throughout. Anything we added or removed he provided details for. His workmanship and integrity were impeccable.”

The architect generated drawings throughout the process but there were no major changes. “Every couple of months there was a site meeting where decisions had to be made but it was all very straightforward. At the time we lived half a mile away, in the local village, and drove past every day. So we were up on site very often, especially when the time came to give the house our own finishing touches. A lot of time was spent on snagging and we were quite involved at that stage.”

John’s advice is to focus on hiring the right architect and builder by doing your homework to find the candidates. “The architect needs to be someone who’s excited and takes your project personally; they also need to communicate with flair, you want to be able to pick up the phone and feel comfortable to suggest a change or ask why something was done a certain way.”

“As for the builder, make sure to visit houses they’ve built, three or four of them, and find out how long their subcontractors have been with them and how solvent they are so they can see the project through.”

Mechanics

The building works began in the summer of 2011 and finished a year later, in June 2012. At the time insulation and airtightness were important but not as essential as they are nowadays due to the changes in Building Regulations.

Therefore the Blacks decided they would go for the basic requirements on insulation and ventilation. The 100mm cavity walls were pumped with expanded polystyrene (EPS) beads; nowadays the cavity would be wider to allow for more insulation or the walls insulated on the outer leaf.

“We chose EPS beads because we felt that was the best way to fully fill the wall,” says John. “With rigid foam panels all around, the window area can be compromised. The beads are pumped into the wall – when they start spilling out you know all of the crevices have been filled.”

“To the underside of the vaulted walls and the dormers we felt PIR boards would fill the gaps just as well. The roof we kept to the minimum requirements but we did put in airtightness membranes all around the building to prevent cold air seeping in.”

With airtightness comes the need for ventilation and to satisfy Building Control, John chose to go for a standard set-up: trickle vents on windows, extractor fans in bathrooms/ kitchen, and an open vent in the living room for the stove.

The problem with open vents are draughts, which the architect solved by placing a hole in the hearth and directing the ducting straight down to the garage below, which has an opening in the exterior wall. This reduces draughts to the main room as the ventilation is essentially happening through another room, acting as a buffer.

The heating system consists of a 97% efficient condensing oil boiler backed up by a 20kW stove with back boiler (4kw to room, 16kw to boiler) in the living room which the Blacks feed with coal, peat and timber. There’s underfloor heating downstairs, in the living area, and the rest of the rooms are zoned with radiators.

Yet the house doesn’t consume a lot of energy. It is insulated and airtight but also benefits from south facing windows and the ability of the concrete floors and walls to retain heat during the day and release it at night. “Before moving in, we were living in a home built 12 years previously and in comparison, our oil consumption has come down dramatically. I’m especially impressed with the back boiler, it’s amazing.”

They are adding another stove in the snug, one which won’t be plumbed into the heating and hot water system. “We had initially envisaged an open fire in there but we prefer to have the stove and close off the flue when not in use, it maintains a contemporary feel to the room, whilst still being practical.” Also, most of the heat generated by an open fire is lost up the chimney.

Childhood home

With a young family, it’s common to want to build your own home. Both John and Susan grew up in the countryside and they wanted their children to benefit from that experience. “At the beginning of the project we had two children and after we moved in another one came along,” says John.

However on a site like this there are always certain dangers. “With the building works we got the paving and kerbing done but have since added ranch fencing for safety, as we’re so close to the road and the river we needed something secure for the children. We have subsequently landscaped the gardens and completed the drive, allowing the children space to ride their bicycles and play outside.”

“Then there’s the fact that we had to leave the windows easy open because of fire regulations but we need to start thinking of a lockable system,” says John. “We’re on three storeys so they’re a bit of a hazard.”

Inside the house, while the three storeys do represent a greater need for stair gates, the split levels provide plenty of half landings which are easy-access and manageable. What started off as a difficult site turned out to be the inspiration for a custom-built family home.

Suppliers

Architectural designer

FMK Architecture, Ballymena, Co Antrim, tel. 2588 2213, fmkni.com

Builder

George Robinson, Ballymena, Co Antrim, tel. 2564 8444

Tanking membrane

Visqueen, visqueenbuilding.co.uk

Bathrooms

Ballycastle Homecare, Ballycastle, Co Antrim, tel. 2076 2311, ballycastlehomecare.co.uk

Kitchen

Kitchen Concepts, Ballymena, Co Antrim, tel. 2565 8111, kitchen-concepts.co.uk