How Cora Marshall and Philip Clarke converted their compact 1950s two-up-two-down house into a bright and spacious family home.

[adrotate banner=”44″]

In this article Cora and Philip take us through their Dublin extension project, including:

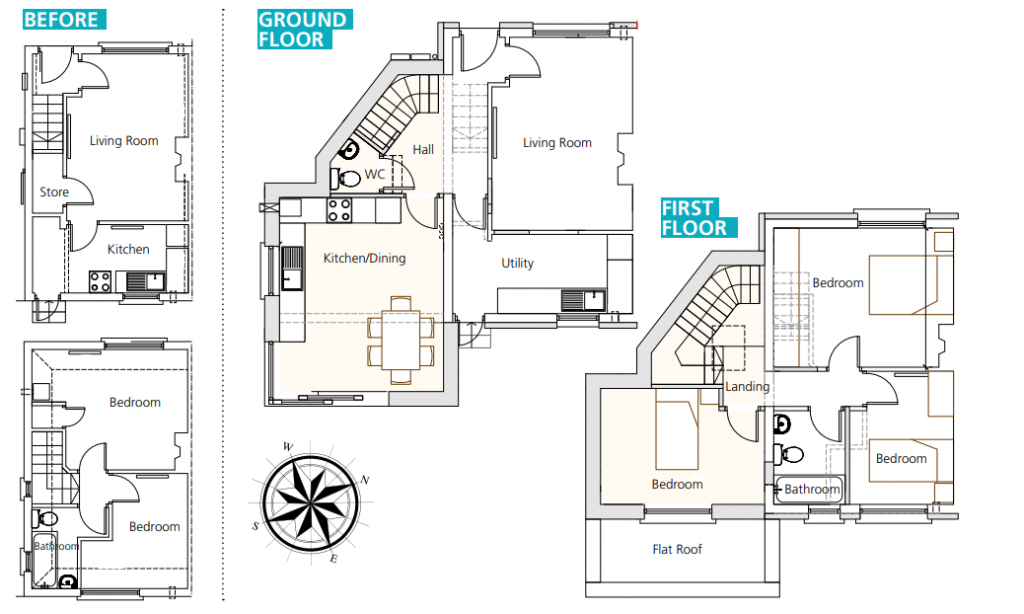

- Working with an architect and extending at the side of the end-of-terrace concrete house

- How to extend and maximise garden space with before and after floor plans

- Moving the internal staircase

- Details of the external wall insulation work

- Window replacement

- Securing a self-build mortgage

- Redesigning the plans to the budget

- Construction drawings for the extension project and for future alterations

- Builder contract details

- Demolition work, moving out and the need to replumb

- Snagging

“My sister originally owned this house and I always loved it,” says Cora. “The garden is great. She bought it in 2005 and when she moved out to live with her partner, she rented it out. Phil and I liked it so much she sold it to us in 2017.”

Size before: 55qm

Size after: 100sqm

Total cost: €130,000

BER: F1 upgraded to a B2

Walls: insulated externally with 120mm EPS with silicone silicate render (which is, according to the architect, hydrophobic and has better self-cleaning properties than acrylic renders) onto existing solid concrete walls or on the new build over 215mmm solid concrete blockwork. U-value 0.2 W/sqmK

Roofs: insulated with 50mm PIR insulation fixed to underside of joists with airtightness tape to joints and junctions with walls. Plasterboard and skim plaster finish to ceiling. 200mm fibre insulation between rafters above (sloped sections of roof insulated with 100mm PIR insulation between joists fitted flush to underside of rafter and 50mm PIR insulation to underside of rafter).

Existing solid ground floor: which featured a tar/pitch DPM above the original slab was retained and damp-proofed from above before floor finishes were applied. Conventional insulated concrete slab construction was employed to the new extension.

Dublin extension plans

This terraced house was built as part of a push to increase the Dublin housing stock, in the days when city limits were expanding. Made of solid concrete walls and to a distinctive style, it presented the perfect opportunity for a makeover. Cora and Phil found Fergal their architect through an acquaintance and started on the project straight away.

“We wanted a third bedroom upstairs and a two-storey extension, we also wanted a bigger kitchen so we could fit a table in there. On the wish list was also a music room,” relates Cora. “Our Irish music instruments take up a lot of room. It would be nice to have a piano too.”

“Fergal said that a good way to extend was to the side of the house instead of at the back, to encroach as little as possible on the garden. He said the side of the house was wasted space – the old maxim of building on the worst part of a site applied in our case. The fact that the house was end-terraced allowed us to move the stairs from the original house and create a spacious top-lit stairwell in the new extension,” explains Cora.

Moving the stairs is what made this Dublin extension project such a success. “We would no longer need to use the living room as a hallway to access the stairs and it allowed us to change the layout and room sizes upstairs and down.” The shape of the site created an interesting cranked shape for the stairs which they finished with feature painted timber panelling and concealed doors to the wc and storage under the stair flight.

External wall insulation

“A lot of houses in the area have insulated their homes from the outside,” adds Cora. “One reason is that the walls are solid concrete and that’s a type of construction that lends itself to external wall insulation. But I think it’s also because you don’t lose any internal floor space, and the window reveals are not as deep which I think is also quite nice.”

External wall insulation works best when new windows are being fitted and moved forward to the front face of the external walls, as was done here. “There was also only a small area of the original wall left exposed, on the side facing the street and on the first floor of the rear elevation. It therefore made sense to wrap the entire house to create a thermal-bridge free external envelope,” explains Fergal.

One tricky area in terms of detailing was the existing concrete eaves which is a feature of this type of house throughout Dublin. “We could have created a thermal bridge at this point so we over-cladded the eaves with a thin covering of external wall insulation and placed aerogel insulation above the concrete eaves,” adds Fergal.

With the work on the external wall insulation also came the need to replace the windows.

“It took us a while to choose the window colour and the door,” says Cora. “The windows in general took time to make a decision on; Fergal designed them for us but we were debating whether or not we should replicate the panels. Fergal advised us against it; because the frames are so thick it wouldn’t have looked right.”

“The old windows were single glazed with small panes and having replaced them we do get more natural light in the house now,” continues Cora. “The front door is bright yellow, we went for primary colours. Some people thought the colour was a temporary one but we love it.”

‘…the shape of the site created an interesting cranked shape for the stairs’

Budgeting the Dublin extension project

The initial stumbling block was securing the mortgage. “We had to get the amount we were to borrow to match the valuation of the house plus the cost of doing up the house. The bank sent their own valuer and we had to produce a cost for the renovation from a builder; we got someone our structural engineer recommended to price it up for us.”

“We were ambitious at first; the original plan included a music room connected to the open plan kitchen/dining area. We didn’t have enough money to build that extra room so there was a bit of back and forth with the design and valuation before we could secure the mortgage.”

“Fergal put together the construction drawings so that this additional living room could easily be added onto the house in later years as the budget would allow but we didn’t put in the foundation at the time they were poured. It would have added too much to the cost. We don’t really need the extra space, we already have a spare bedroom,” says Cora.

Breaking ground on the Dublin extension project

“Even though the design only took a month to put together, it probably took five months to sort out the valuation and secure the mortgage. Planning permission after that took no time at all. We went to tender quickly too, we had a choice between three contractors, and in May 2017 we broke ground.”

“We’d just had a baby at this stage, who was born in February,” adds Cora. “So as soon as the three-week groundwork period was done, including demolishing the shed, we moved out.” The contract with the builder excluded the floor coverings, the kitchen and painting. “My dad used to make kitchens with a neighbour of his and so we went with that company,” says Cora.

“We had ideas of what we wanted, such as the handles recessed into the doors, but we also got some extras like the pull-out spice rack which we hadn’t originally planned for. We were going to go with quartz for the worktops but to keep costs down we chose a laminate and we’re happy with it.”

“From June to October we were in between houses, I was on maternity leave so spent some time home in Longford. We were hoping to move back in September but we had to do some extra work on the house we hadn’t originally anticipated.”

The house had lead pipes. “We had to replumb the entire house. We were moving the boiler anyway, from a bedroom to the new utility room, so had some of it budgeted for. The gas boiler was fairly new and didn’t need replacing but it was nice to get rid of the electric showers when we realised we actually didn’t need them.”

“What we really didn’t expect was having to rewire the entire house,” continues Cora. “It had only been done 10 years ago but the electrician wouldn’t certify the whole house without redoing it entirely. Then of course we had to replaster all of the walls because of this intrusive work.”

Some other unexpected work had to do with the floorboards in the sitting room which had to be replaced as it turned out they were rotten; they also had to treat some of the timbers in the attic when they insulated it.

Apart from the unforeseens there were very few headaches on site, one of which was skip/storage space to the front without encroaching on the neighbours’ parking. “Site access was also tricky at times to get materials in and out. We had no structural issues as the house is solid concrete so it was straightforward knocking through walls.”

In terms of the snag list, there were only a few teething issues with the plumbing. “We had hot water going into the toilet – it was nice to have a hot cistern but not the most efficient of features! There were a few leaks but the builder came to fix them on the day. Because of the trouble we had, he told us he would guarantee all plumbing for two years. We haven’t had any trouble since.”

The verdict? “We love the house, it’s very warm and flows so well. We’re also really happy to have a utility room, which was the old galley kitchen. When we come in from the garden that’s where we enter the house, it’s also where the bicycles are.”

A house truly made for family life.

Q&A

What surprised you?

The logistics of it all. For a while it seems like the build is going nowhere but then it moves very fast. All of a sudden you’re at site meetings every week instead of every two to three weeks. We had a long discussion about the stairs, trying to get them to fit into the space properly but it was all sorted out between the builder and Fergal. Also it was more difficult than I thought it would be to coordinate the arrival of the plumber with my brotherin-law who did the flooring. But everything worked out in the end.

Would you do it again?

We don’t plan to but I suppose you never know!

What’s your favourite part of the house?

I love the stairs and the kitchen – it’s so quiet and peaceful. Looking out onto the garden is wonderful.

What single piece of advice would you give someone thinking of renovating?

Definitely get an architect; they have the best ideas for designing the house. And don’t wait too long to get started. We did it at a difficult time between the new baby and mom sick, but if you keep the end goal in sight you can remind yourself it’ll all be over soon and you’ll be delighted with it. If we hadn’t done it then, I don’t think we would’ve done it for another 20 years.

What would you change?

I’d get the landscaping done professionally. If we had more money we would have – I see my sister who built a house and in the blink of an eye it was all done. In our case we levelled and seeded the garden ourselves and my dad did the decking for us.

Dublin extension top tips

Write everything down. Make sure to jot everything down that’s agreed to at the site meetings. The architect will be on call to guide the builders but you will want to stay in control of the build as well.

Get a grant. We got three grants from the Sustainable Energy Authority of Ireland, for the attic insulation, external wall insulation and a small grant for installing heating controls. We have three zones, one for hot water, the others upstairs and downstairs. The zoning has made a huge difference to the way we use the house and saves on the heating bills too.

Have fun choosing colours. We took our time picking the colour for the windows and doors but for the staircase too; the inspiration came from a photograph I saw online. The blue really lifts the hall up. Fergal designed the panelling for the hidden door and to highlight the shape.

Reuse what you can. We kept old doors and fireplaces which we reused in the old part of the house; it keeps the character of the building. Even though we went with external wall insulation we made sure we kept the band on the front of the house to match the rest of the building.

Factor in builder’s holidays. We had them fall in the middle of the project; that meant the window suppliers took two weeks off which in turn meant we were in a rush to get the order in.

Suppliers

Architect: Fergal McGirl MRIAI, Dublin 1, tel. 01 873 5441, fmgarchitects.ie

Energy assessor: IHER Energy Services, Dublin 3, tel. 01 4548300, iher.ie

Kitchen: Raymond Mcloughlin of Kilsallagh Woodcraft, Edgeworthstown, Co Longford, tel. 043 667 1704, kilsallaghwoodcraft.ie

Builder: Michael Creedon, Naas, Co Kildare, mobile 087 917 3672, creedonconstruction.ie

Roof insulation: Fibre insulation Moy Metac, isover.ie

Floors: Gerry O’Dowd of Advance Flooring, Dublin 12, tel. 01 626 8940

Decking: Seán Marshall – Grant: Better Energy Homes, seai.ie

Thermal-bridge information at eaves detail: DIT School of Architecture – Digital Analysis in Energy Retrofit course which studied this exact building type as a project in 2015, dit.ie

Photographer: Dermot Byrne Photography, dermotbyrnephoto.ie